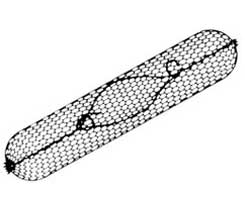

Sack gabions consist of a single mesh panel

Sack gabions consist of a single mesh panel and are supplied with steel reinforcing wires inserted during the manufacturing process. The wire used in the manufacture of the sack gabion is heavily zinc coated soft temper steel.

Sack gabions are filled with rock at the project site to form flexible, permeable, monolithic structures used for emergency and river training works where local conditions require fast installation or where the water does not allow for easy access to the site and where underwater installation is necessary.

|

Size of Gabion

|

||

|

length of cage (m) |

diameter of cage(m)

|

V (m3) |

|

1.8

|

0.6

|

0.54

|

|

2.7

|

0.6

|

0.80

|

|

1.8

|

0.9

|

1.2

|

|

2.7

|

0.9

|

1.80

|

If you're looking for a specific product that isn't in the list.

Please contact us, there are expert advice special for you according to your application and budget!

Contact UsCharacteristics of Gabion Mesh Sack:

- (1) Economic and useful: What we need to do is just put the stones into the cage without special skills.

- (2) It is convenient to transport as it can be transported folded, assembly on site.

- (3) It has a strong resistance to natural destruction and poor weather.

- (4) It can withstand large-scale deformation, and does not collapse.

- (5) Some plants can grow in the gap among the rocks, and it can melt with the natural environment surrounding together.

- (6) And it has good permeability, which can prevent the damage caused by fluid static.

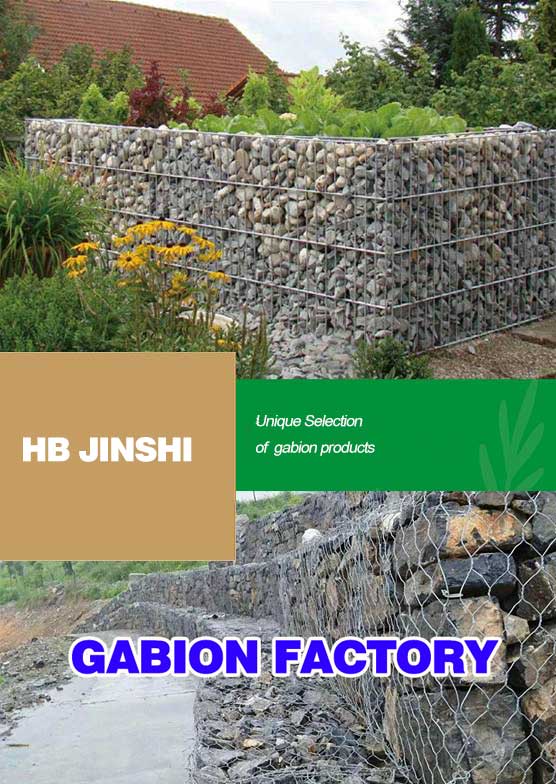

Uses of Gabion Mesh Sack:

Gabion Mesh Sack can be widely used in highways, railways, protecting hillside, hillside greening, well and alley fence, building and breeding, zoo fence, greening fence, hillside net cage, flood fighting net cage, revet fence, control and guide the direction of river, spillway and diversion channel, rock fall protection, prevent soil and water from flowing, beach protecting project, protection of the bridge, solid structures defense project, retaining wall, and port project, etc.

We control and check the producing procedure sincerely and all of the wires are sincerely to ASTM A975-97, i.e tensive strength is above 75000psi515MpaASTM A641/A641M-03